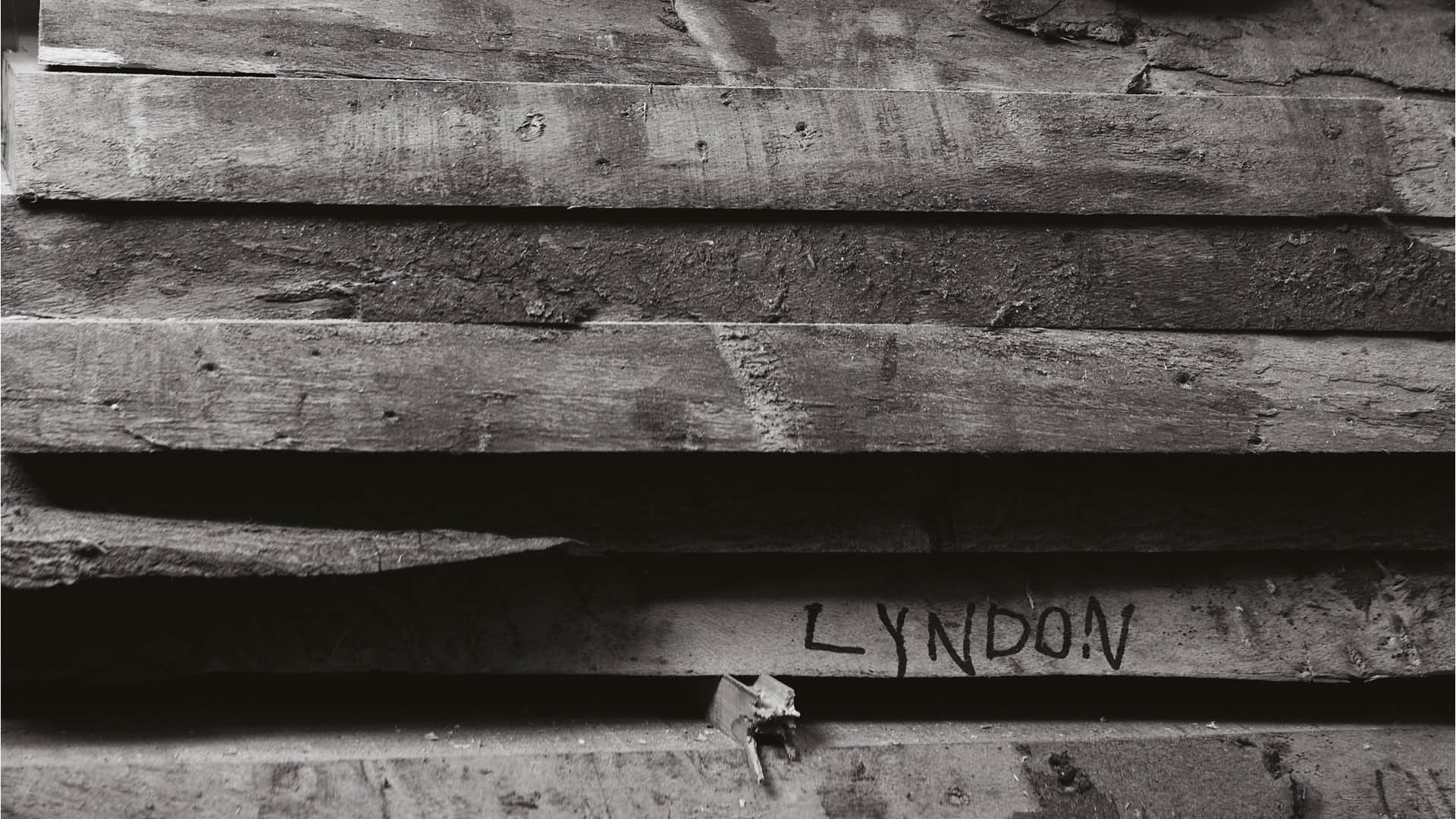

from Raw Timber

to Crafted Comfort.

Wood. It excites us, and it’s central to what we do. To get the most out of it, our process entails superb craftsmanship, intuitive design and attention to detail…

When shipments of timber arrive at our workshops in Cheltenham, we stack the boards and planks by size and species in the woodstore to dry. Even as it arrives from the mill, wood is an inspiring material – raw and rough, warm in colour, the scents of sawdust and resin evoke the wild forests where it grew. Unique wood grain textures compete with the saw blade patterns and we begin to imagine how might look when formed and finished as pieces of high quality furniture.

Natural, high-quality timber

‘Nature’ is front of mind in three senses when we source our timber. Firstly, there is our commitment to the environment and sustainability. When sourced responsibly, wood is a renewable resource and that’s one of the reasons why we’re passionate about it. We insist on the highest quality wood from FSC certified suppliers who replant and replenish their forests, the new growth sequestering CO₂ from the atmosphere.

Secondly, with its colour, grain patterns, textures and even its knots and imperfections, wood brings nature into our environment. Timber furniture has biophilic qualities that can help soften the hard, industrial world around us. Designing furniture with minimal, organic lines and using materials from nature, we’re able to create oases of calm and tranquillity in hospitality and workplace environments.

Thirdly, wood is nature’s ideal building material. High quality furniture, expertly worked and formed by our craftspeople, can last a lifetime. The longevity of our products and the fact that wood is recyclable, makes our products more sustainable and therefore better for the natural world.

Traditional joinery skills

Whether it’s building the internal frames of our Bodie and Orten sofas or expertly applying the finish to their show-wood elements, traditional woodworking and joinery skills are at the heart of everything we create. The knowledge, experience, perfectionism and craftsmanship of our furniture makers has come down through the generations, and we’re proud to keep these skills alive in Britain.

Our woodworking team works closely with our designers to ensure each product is conceived so that it can be produced in the best way. We honour those traditional skills by incorporating them visibly in Lyndon furniture. The smooth, contemporary lines of a piece will combine with joints based in traditional woodworking practice for furniture that embodies a modern aesthetic and traditional knowhow.

Innovating with wood

Our investment in leading-edge computer numerically controlled cutting and forming machinery enables us to combine our age-old woodworking skillsets with 21st century technology. Providing precision, the efficiency and flexibility of this equipment means we can sculpt components from solid hardwood in new shapes and forms resulting in furniture that beautifully balances the modern and the traditional. With this blend of technology, we are able to reduce offcuts and limit waste wood,

but more than that it means we can explore new frontiers in furniture design and manufacture.

Crafted comfort

While the timber structure of Lyndon furniture oozes warmth and natural tactility, this is complemented by the soft cushioning and precise stitching of our upholstery. Lyndon’s expertise in foam cutting is second to none, our pattern cutters are among the finest in England and our machinists finish every single seat, back and cushion to the most exacting standards. With their minimal lines and smooth curves, the forms we create are modern in style, while traditional details in the buttoning, piping, quilting and stitching add touches of character and a nod to our heritage as British furniture manufacturers.